Sanitizing the Processing Environment

There is no higher imperative for those in the food industry than ensuring the delivery of safe products to customers; maintaining a clean and pathogen-free processing environment is a critical element in fulfilling this mission. Contamination from environmental pathogens such as Listeria monocytogenes, or cross-contamination from pathogens with zoonotic origin such as Salmonella can cause major disruptions, especially if recalls are necessary. Any contamination can have a severely negative impact on a company’s reputation.

Published on:

Microbiology

How to clean a processing environment

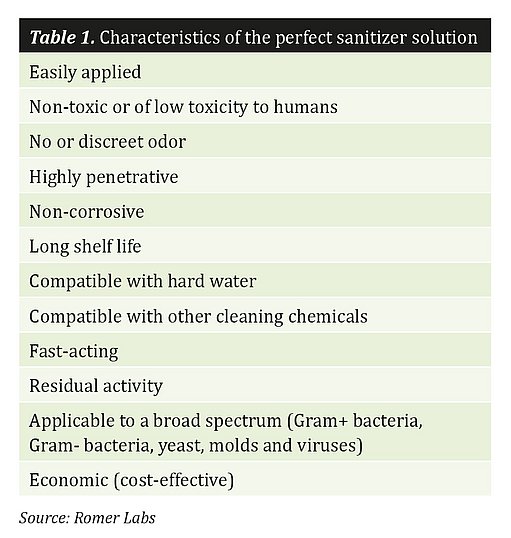

In sum, food processors can ensure that their processing environment is clean and sanitary by removing deposits and then by applying a sanitizer or disinfectant to reduce the number of residual microorganisms. Often referred to as “pre-cleaning”, the mechanical or physical cleaning is an important first step in any sanitization program. A mechanical cleaning increases disinfectant efficacy, and, in some cases, enhances log reductions. Several products for disinfecting and sanitizing surfaces are available to the food industry and have proven themselves useful in processing environments. In practice, a disinfectant, once selected, will remain the same for decades. Table 1 lists the most important considerations when choosing a sanitizer. Here, we review the significant differences between cleaners, disinfectants, food contact sanitizers, sterilants and neutralizers.

Cleaners

A cleaner is a detergent that assists in the physical or chemical removal of soil, dust, organic matter, and allergen residues. Usually, it is intended for use on specific areas (e.g. floors, walls, tables) and can be used on surfaces that come into contact with food. Cleaners may remove significant numbers of microorganisms, but they do not kill or eliminate them. Additional agents are required to disinfect or sanitize the surface.

Sanitizers

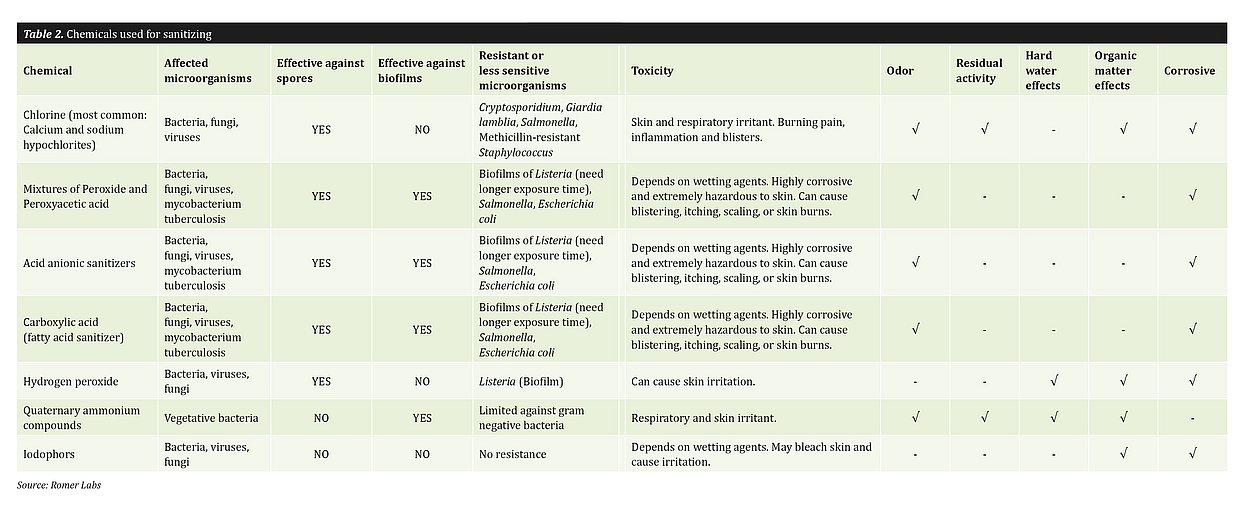

Sanitizers reduce but do not eliminate all microorganisms. Generally, food processors use them as part of good hygiene practice to reduce or eliminate pathogen contamination risk. A list of sanitizers is shown in Table 2.

There are two types of sanitizers:

- Food contact sanitizers with disinfectant capabilities; these can be used on surfaces that come into contact with food and (also known as food contact surfaces, or FCS's).

- Non-food contact sanitizers can only be used for surfaces that do not come into contact with food (Non-FCS's).

Disinfectants

Broadly speaking, disinfectants include a combination of bactericides, fungicides, virucides, mycobactericides, tuberculocides, sporicides, and sterilants. There are various regulations governing how to test the efficiency of disinfectants. These tests generally verify the concentration of the disinfectant needed to kill certain microorganisms. The use of a disinfectant is appropriate for frequently touched surfaces and surfaces likely to harbor pathogens.

Sterilants

Sterilants not only reduce, but also destroy all types of microorganisms. They must demonstrate an absence of growth in test samples, or at least a 99.9999% (106 log) reduction. Sterilants include specialized chemicals such as glutaraldehyde, formaldehyde, and peroxyacetic acid. The term sterilization also refers to the non-chemical elimination of microorganisms using either dry heat (as in ovens) or moist heat (using steam under pressure or autoclaving).

Neutralizers: Which one to choose?

Sampling sites may be covered with residue from disinfectants used during the sanitation process. Food contact surfaces are often rinsed with fresh water after disinfecting and therefore may contain no or only negligible amounts of disinfectants. Sometimes, operators neglect to rinse drains, floors, walls and machine parts, with the result that these continue to harbor disinfectant residues. Microbial growth may be inhibited by these chemicals, but these remaining microorganisms are still alive and present a potential and ongoing pathogenic threat.

For microbiological sampling, it is vital to inhibit the effect of disinfectant residues. This is why sampling devices are pre-moistened with solutions that provide efficiency in neutralizing. Some of the most important neutralizing solutions are Dey-Engley Neutralizing Broth (DE), Letheen Broth (LB) and so-called “neutralizing buffer” (NB), although there are also many other proprietary buffers on the market.

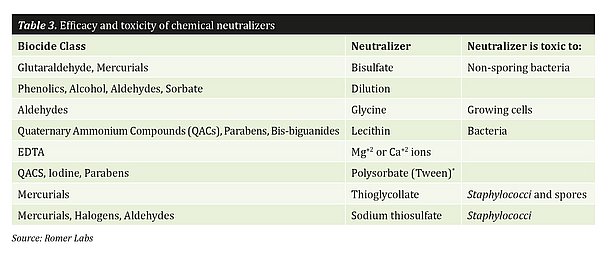

When it comes to choosing the right neutralizing solution, there are two main considerations: the toxicity of the solution itself and the efficiency of the neutralizing biocidal agents. The toxicity should be considered because the agents will also interact with the microorganisms, disturbing or even stopping their growth. As listed in Table 3, each biocide has its corresponding neutralizer. With each additional unnecessary neutralizing agent, the potential for harm to the target microorganisms increases.

While the type of neutralizer used in microbial sampling depends on which disinfectant is used, market availability is also a deciding factor. One of the most widely used neutralizing broths is Dey-Engeley broth. Developed by Dey and Engley in 1970, it has become one of the most effective neutralizing broths primarily owing to its broad range of neutralizing efficiency.

It is not insignificant that AOAC International refers to it. A sugar source and a pH indicator was added to it, making it useful for sterility testing. A drop in the pH value indicates the growth of sugar-fermenting bacteria by turning the solution from purple to yellow. Yet this change in color is not necessarily helpful, as the subsequent detection or counting step after sampling renders it superfluous.

Conclusion: customized solutions

Overall, deciding which chemicals are used to clean the processing environment and which neutralizers are used for microbial sampling are very specific to the requirements of the company. In-house evaluations are necessary to determine which chemicals and methods fit best.